LERAM When the UPPA tends URGO’s woundsA tool able to detect defective adhesive tape during manufacturing in URGO plants

Researchers of the LERAM common laboratory have developed a tool able to detect defective adhesive tape during manufacturing in URGO plants.

Photo: Francis Ehrenfeld (left) and Anthony Laffore (right)

Making an ordinary sticking plaster is no mean feat, as URGO, the second European manufacturer of plasters, is well aware. Before they end up wound around your finger, plasters are made from huge rolls of adhesive tape, several kilometres long, that rotate at high speed on automated production lines. To check the quality of the tape, a sample is taken over a period defined by URGO. In the line of sight: the adhesive parameter. The slightest defect is a no-go. If the adhesive properties do not correspond exactly to commercial specifications, if the tape sticks too much or not enough, the machine is stopped immediately, and part of the production is lost. It was to counter these losses, that the URGO research teams decided to call on the researchers of the IPREM in Pau with whom they have been sharing the LERAM (Laboratory for the study of rheology and adhesion of wound dressings for medical applications) since 2013.

A patent and an operating permit

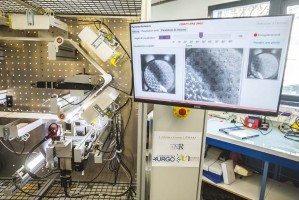

Christophe Derail, the Director of the LERAM, Francis Ehrenfeld and Anthony Laffore, both instrumentation engineers at the IPREM, got down to work straight away. They came up with the idea of an innovative tool to measure the adhesive parameter almost in real time, without it being necessary to slow down or stop the production line. This is called online measurement. “For this purpose,” Christophe Derail explains “we designed a roll that brushes against the adhesive tape over the period defined by URGO. When it rotates, the roll generates a slight stress on the moving adhesive tape. By measuring the stress on contact with the adhesive tape by means of judiciously positioned sensors, we obtain extremely precise information on the properties of adhesion. Coupled with an optical device designed to corroborate the results of the analysis, the technique is 100% effective for detecting any discrepancies, in other words adhesion defects.” A real stroke of genius, which reduces the amount of tape wasted while helping to save production time; it could also turn out to be a very valuable development tool. The first test bench was built and successfully tested in the laboratory, and the second is to be installed very soon on URGO’s premises. As a result of this research, an international patent was filed and an operating permit for the technology was signed with the industrial group. Innovation is in the air, at the UPPA and at URGO.